$30K Ford Electric Truck Coming In 2027 Is Seriously Bad News For Slate

- Ford is launching a brand new mid-size, four-door EV truck in 2027.

- Pickup will be as fast as Mustang Ecoboost and roomier than a RAV4.

- Ford also revealed it’s killing the Escape and Lincoln Corsair SUVs.

Ford promised a Model T moment this week, and the news it just dropped is undeniably huge. The headline is that a new $30,000 compact electric truck is in development and will arrive in 2027. But the story is much bigger and involves an entire family of affordable EVs that will follow in the truck’s wake.

More: Ford Delays Big EV Truck Again But Something Smaller Is Coming And It Could Be Named Ranchero

But let’s deal with the pickup first. Ford says it’s a four-door midsize electric truck, meaning it will fit in the range below the existing F-150 Lightning. It’ll start production in Ford’s Louisville plant in Kentucky two years from now, and will cost $30,000 – and that’s an MSRP, not a with-tax-credits price, because credits are being axed this September. Ford says the price matches what the Model T cost a century ago, adjusted for inflation.

Quick Like a Mustang, Roomy Like a RAV4

If this is already starting to sound like bad news for startup Slate Auto and its back-to-basics Slate electric truck, things only get worse. Instead of around 8 seconds to 60 mph (97 km/h), Ford says its electric pickup – which could be badged Ranchero – will be as quick as an Ecoboost Mustang, suggesting 5-second-grade performance. It even claims the truck will have “more downforce” than the Mustang.

And Ford also promises the four-door cabin will have as much interior space as a Toyota RAV4 SUV, says it has a frunk to give a car-like cargo bay, and a lockable bed that can swallow surfboards and other outsize gear.

A Platform with Range

The EV rides on a brand new flexible electric platform that will spawn a huge family of other EVs, some very different from the truck, judging by Ford’s presentation. One gif showing the different types of vehicles the platform could accommodate showed everything from two-seat vans to three-row SUVs.

Compared with a conventional platform, the new architecture has 20 percent fewer parts, 25 percent fewer fasteners, requires 40 percent fewer plant workstations, and reduces build time by 15 percent, Ford claims. It also suggests the resulting vehicle will cost less over five years of ownership than a Tesla Model Y does over three.

“The numbers tell the story” Farley said. “Take for instance the wiring harness in the new midsize truck; it will be more than 4,000 feet (1.3 kilometers) shorter and 10 kilograms lighter than the one used in our first-gen electric SUV.”

Ford plans to cut costs further by equipping the truck with lithium-iron-phosphate (LFP) batteries. These packs are designed to be lighter and more compact, and they will double as part of the vehicle’s structure, forming the floor as well as the battery housing.

“We took inspiration from the Model T – the universal car that changed the world,” said Doug Field, Ford chief EV, digital and design officer. “We assembled a really brilliant collection of minds across Ford and unleashed them to find new solutions to old problems. We applied first‑principles engineering, pushing to the limits of physics to make it fun to drive and compete on affordability. Our new zonal electric architecture unlocks capabilities the industry has never seen. This isn’t a stripped‑down, old‑school vehicle.”

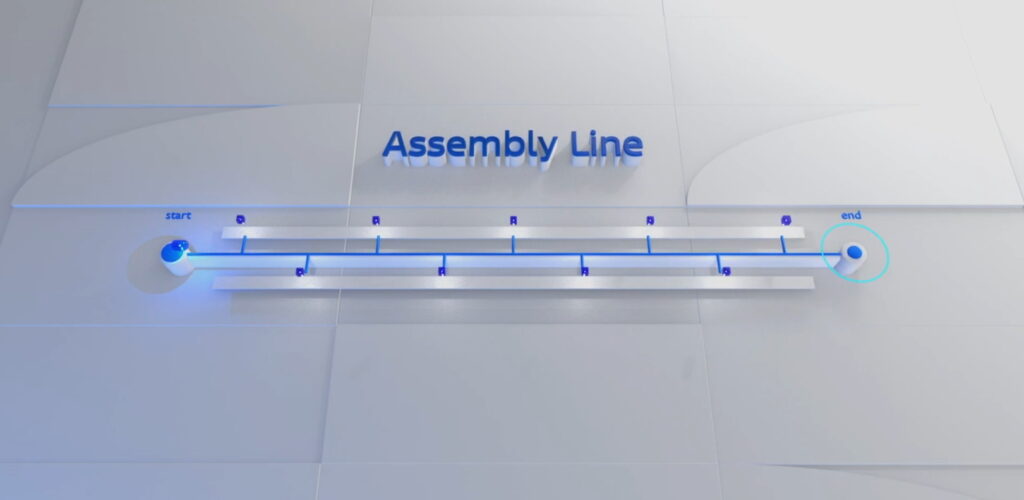

An Assembly Line Reinvented

The company will overhaul its manufacturing process with the Universal EV production system, replacing the traditional straight-line assembly with a branching “assembly tree.” In this setup, the front, rear, and structural battery pack are built on separate lines at the same time before being joined in final assembly.

Large single-piece aluminum castings reduce the number of parts, while pre-organized kits provide workers with all tools and components in the correct position, improving speed and ergonomics. According to Ford, the design “dramatically improves ergonomics for employees by reducing twisting, reaching and bending, allowing them to focus on the job at hand” .

Ford says the approach will make assembly of the midsize electric truck up to 40 percent faster than current Louisville-built vehicles, with part of that time reinvested in insourcing and automation to raise quality and lower costs. The net result is a 15 percent overall speed increase.

End Of The Road for Escape, Corsair

The arrival of Ford’s new generation of EVs at Louisville means the end of the road for the company’s Escape compact SUV as well as the Lincoln Corsair, both of which are currently assembled at the Kentucky plant.