Dacia Adds Two New Models And Neither Will Be Built In Romania

- One of the new models is a wagon above the Jogger.

- Another model, based on the electric Twingo, is near.

- Dacia now builds only Duster and Bigster at home.

Dacia is Romania’s largest and most important car manufacturer, and this year it is preparing to expand its lineup in a meaningful way. Two all-new models are on the way, yet neither will actually be built in the company’s home market.

The first arrival will be a new wagon with crossover elements, currently known as the C-Neo. Positioned above the Jogger in Dacia’s range, it is intended to tap into the ever-growing compact segment.

Read: India’s New Renault Duster Looks Like A Rich Man’s Dacia Duster

Initially, Dacia planned to build the C-Neo in Romania. However, Romania-Insider reports that production will instead take place in Turkey. That decision leaves Dacia’s Mioveni plant in Romania focused exclusively on the Duster and Bigster.

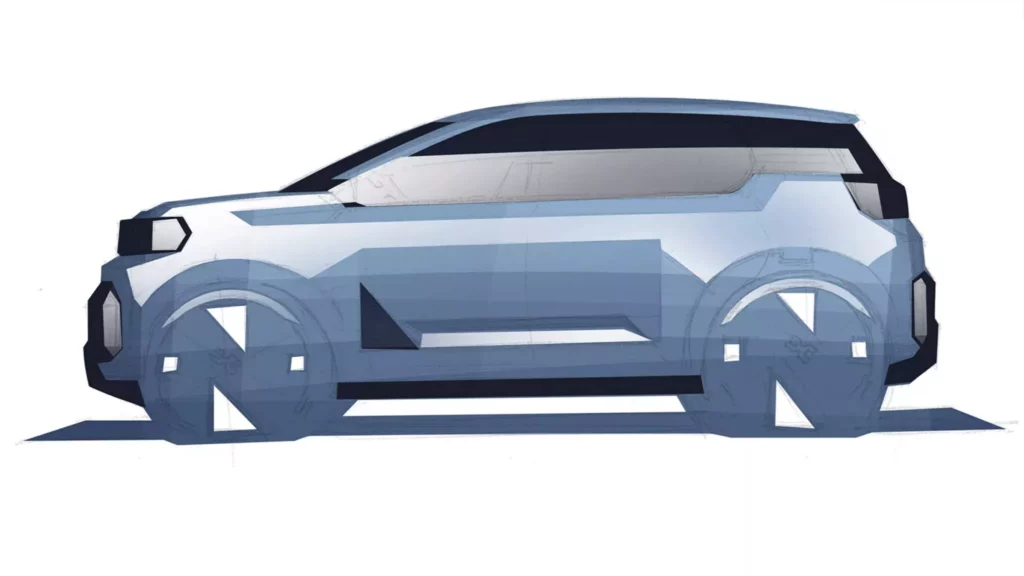

SHproshots

The C-Neo will be underpinned by the existing CMF-B platform and should be offered with a slew of different powertrains, including gas, LPG, mild-hybrid, and full-hybrid options that use a 1.2-liter turbocharged three-cylinder.

Visually, Dacia says the new wagon will follow in the footsteps of the Sandero Stepway with rugged design elements, likely including muscular fenders and roof rails.

A New Electric City Car

Just as significant is Dacia’s upcoming electric vehicle, which will be based on the Renault Twingo. It will not undercut the China-built Dacia Spring on price, but it is expected to start at around €18,000 or just over $20,000. That still positions it as one of the more accessible EV options in Europe. Production of this new addition will take place at Dacia’s Novo Mesto plant in Slovenia.

Dacia has identified the A-segment as an important growth driver in the broader EV market, hence why it’s launching a new model to compete. A single teaser image of the car has been released, revealing that while the proportions may be similar to the Twingo, it will look nothing like its French sibling.

Beyond these new models, Dacia already produces the Sandero and Jogger in Morocco to take advantage of the lower manufacturing costs. The approach reflects how the brand now operates as an international manufacturer, not one anchored solely to its Romanian base.