Every maintenance professional has their own unique way of going about their craft, and every bus garage has its own feel. But when experts discuss approaches to parts purchasing and inventory management, certain best practices rise to the top.

For starters, fleet uniformity goes a long way toward achieving reduced downtime, mechanic familiarity with equipment, effective inventory management, and cost containment, explained a group of fleet directors and lead mechanics, some having earned the designation of School Transportation News Garage Stars in recent years.

“The last 15 years weve been buying Blue Birds,” said Chad Eaton, fleet manager with the Eagle County School District in Colorado. “It just simplifies everything: inventory, repairs, training. If you’ve seen an issue once on a Blue Bird, the next time it comes up, you know exactly what to do. It might take you 10 minutes instead of a half hour.”

Ryan Waters, head bus garage technician with the Lake Shore Central School District in Angola, New York and a 2024 Garage Star, agreed that “standardization” is a foundational best practice. “That helps us the most. If we run the same lights, the same tires on everything, we have to keep less parts in stock,” he explained.

Tim Dooley, bus mechanic supervisor at the North Kansas City School District in Missouri, added his district runs all Thomas Built Buses. “It might not always be the cheapest [solution] up front, but standardizing the fleet saves us a lot in the long run, when it comes to stocking parts and training mechanics,” Dooley said. “Keeping one manufacturer simplifies inventory and service. We looked at other brands, but the potential savings didn’t outweigh the added complexity.”

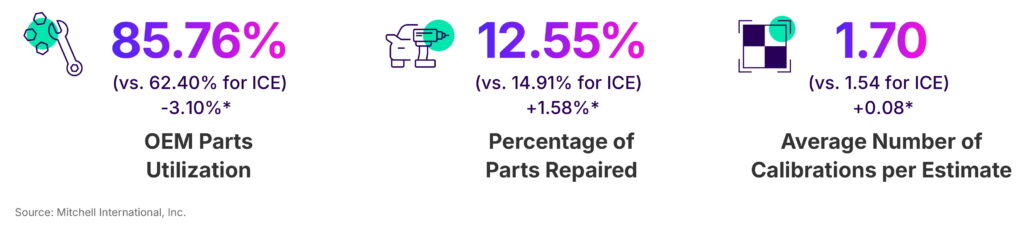

Andrew DeBolt, fleet management coordinator with Californa’s San Jose Unified School District, purchases original equipment manufacturer parts for consistency with service manuals and wear indicators. “Using OEM parts means the wear indicators match the service procedures,” he said. “It keeps everything consistent.”

San Jose also operates with an all-Thomas Built Buses fleet, necessitating fewer parts to stock, a simpler diagnostics process, easier training for mechanics and better pattern-failure predictability.

DeBolt, a 2020 Garage Star, said he operates a hybrid inventory management system that consists of stocking high-use items like tires, mirrors and other common parts while relying on local vendors for just-in-time delivery of infrequent items. He noted the system is streamlined yet responsive to the department’s needs.

“When I started, we had parts for buses we hadn’t owned in 15 years. Now we keep it tight. If we only use it once or twice a year, we don’t stock it,” he said. Proactive maintenance is another must-do, according to the garage experts. “We try to be proactive. If we see it’s close now, let’s just do it,” DeBolt commented. “Don’t wait until it becomes a bigger issue.”

Dooley said an important aspect of maintenance North Kansas manages is inspecting the brakes every time a bus is in the shop. “I keep a spreadsheet to monitor wear, and once a set drops to 30 percent, we schedule the replacement,” he said. “If the bus is already in the shop, we take care of it right then. No sense pulling it twice.” DeBolt applied that strategy to brakes and tires, acknowledging “there is a tradeoff.

“If you’re purely focused on trying to get every last penny out of that tire, you would run it down till it was at its minimum spec and then swap it out at that point, but you run the risk of a collateral issue (such as) a tire coming apart, taking out mud flaps and doing body damage,” he said. “Even if they have 8/32ths of tread left, we say, ‘They’re 10 years old and they’re coming off the bus.’ We sacrifice a little bit of service life on a brake pad or a tire, but we’re saving two weeks of shop time by the time we cut the mangled metal back, weld it and get it undercoated.

San Jose Unified, which buys tires through California’s state school bus tire program to secure better pricing, opts for recaps on rear axles to stretch tire life and save dollars. But DeBolt noted the COVID-19 pandemic, which kept students at home and buses off the road for an extended period, skewed maintenance cycles and caused some tires to age out before wearing out.

“We save 50 percent with recaps, but only if the tire’s being consumed in three or four years. Now we’re seeing 10-year-old tires,” he said. “All these tires that we had been using for recap on the rear axle, now they’re so old they’re failing. It kind of caught up to us.”

Waters’ department in Lake Shore, which maintains 57 buses and another 20 to 30 district vehicles, does use retread tires but does not keep casings longer than five years. When buying new tires, he opts for higher-end Goodyear options that he said improve longevity and cost effectiveness. “Even if you’re buying a tire that’s twice as expensive, if it lasts twice as long it’s less maintenance work for us to do, so it’s worth it in the long run,” he noted.

Waters said he initially tried multiple vendors before settling on one that consistently meets the district’s expectations. A requirement to secure at least three bids and the practice of conducting ongoing price checks with competitors maintains accountability. Decision-making is based on best value and service, not just price. “Sometimes paying a little bit more for a part will get us the better service. Value really does figure into it. It’s just not low bid,” he said.

While the COVID pandemic didn’t significantly disrupt tire deliveries, it did cause major price hikes. Those sharp price increases have largely remained in place. While a simmering global trade war has threatened to increase prices on bus parts from other countries, DeBolt said the uncertainty hasn’t influenced his approach to tire purchases, prioritizing U.S. manufactured brands.

“In the past, we’ve used other brands and had varying levels of success, but we’ve had the best success with Bridgestones, specifically the Bridgestones made in the U.S. And then Goodyears. Their stuff is all made in the U.S., too. The rubber quality is better. The build quality is better.” Does a commitment to purchase quality parts at a higher price fall into the best-practices category? Absolutely,” DeBolt insisted.

Eaton, who has 26 years of experience with Eagle County under his belt, shared a similar philosophy. The district runs only Michelin XZE2s on its bus steer axles and Michelin XDN2s on drive axles. “We’ve been buying these same tires for as long as I’ve been here. The tires are expensive up front, but they last. We tend to age them out before we wear them out,” he said. “It’s about value, not price. We’ve been doing it this way for so long because it works.”

The North Kansas City district contracts its tire work to a company that’s a trusted partner. “They handle most of our tire changes unless it’s something urgent in the morning like a flat. Having that partnership in place really saves us time and keeps our fleet moving,” Dooley said. “We’ve used Goodyear, Continental, BF Goodrich, whatever is available. We don’t have a strong brand preference, but I do feel that Continental and Goodyear wear better than the Michelins that come standard.”

The school district does not run retreads on any of its buses. “Every tire that we put on is new,” he said. “That’s an investment in safety and reliability that pays off in the long run.”

Meanwhile, Eaton said he believes in investing in premium tires for long-term value and buying the same brand and types of tires. “We only need to stock the two kinds of tires steer and drive which really helps us manage inventory efficiently,” he added. Of course, even the top pros have their own approaches to their craft.

When it comes to purchasing, Dooley said he doesn’t spend a lot of time shopping for different prices. “I’d rather work with vendors I trust, who can get me what I need quickly and keep our fleet on the road,” he said. “Midwest Bus Sales knows our fleet, and they’ve talked about going back to a consignment setup, where they stock the shelves and bill us as we use parts. For a district with two garages like ours, that kind of support would be a big help.”

All four districts have made the transition to LED lighting for reliability and reduced maintenance times. Eaton said all of the Eagle County district’s new bus orders come pre-equipped with LED lighting and First Light illuminated stop arm systems and front and back school bus signs.

“We’re even retrofitting our older buses with First Light’s stop arms and school bus signs,” he said. “We’ve had great experience with their products. They’re bright, reliable and add visibility.”

It’s also important to take unique local conditions intoconsideration when purchasing parts and managing inventory.

“Living up here in the mountains in Colorado, we’re required to have drive-line retarders…and we have the exhaust brakes through the Cummins engines we run, so we’re very fortunate that having those two secondary braking systems on our buses means we don’t go through a lot of brakes,” Eaton said.

On the other hand, Dooley noted that North Kansas City goes through brake shoes fast. “About 20 boxes every two weeks,” he estimated. “So, I buy drums and shoes by the pallet. It’s more efficient and more cost-effective to stay ahead of demand like that.”

DeBolt recommended developing and maintaining open, honest and ongoing relationships with the district fiscal department as a budgeting best practice. He avoids “crying wolf” so that his budget requests are trusted and taken seriously.

“When I go to them and ask for money, they know it’s legitimate. That trust makes a huge difference,” he suggested. “We don’t guess with variable costs like fuel. We agree on a number, but we all understand it may need to be adjusted later.”

When possible, Waters makes a point of purchasing from vendors that offer longer warranties and then keeping track of warranties on specific parts. “One company might have a three-year warranty, another one might have a five-year warranty,” he explained.

He said he prefers paperless inspections and maintenance, using a system that automatically generates work orders and alerts based on input. “We don’t have paper in our buses. We have tablets,” he said. “If drivers have an issue, they put it in the tablet. It sends me an email and creates a work order. I can go on there, look at the codes of everything.”

Eaton said investing in training, whenever possible and practical, is another value-added best practice. “We definitely try to get into any training that’s available to keep them up to snuff with standards. But any time you can stay on top of your game in ever-changing industry, that helps cut down on your downtime, too,” he said.

Best practices shouldn’t be shaped by how many or few vehicles a district operates, DeBolt noted. “We’re all driving the same equipment big or small fleet. The best practices don’t change that much,” he said.

Two keys to success above all, DeBolt insisted, are the ability to gather crucial information and roll with the punches. When it comes to the former, he said a search for better fuel economy led to the use of low rolling resistance tires and other cost savings. As to the latter, DeBolt underscored the value of honesty: “Our mantra is, we can deal with anything as long as we know what we’re dealing with.”

Editor’s Note: As reprinted from the August 2025 issue of School Transportation News.

Related: A Jolt to School Bus Maintenance

Related: Technology and Communication: Crucial for Bus Maintenance and Safety

Related: Study: Electric School Bus Reliability, Cost-Effectiveness Stand Up in Montana Extreme Cold

Related: 2025 Garage Stars Announced: Relying on Training

The post Parts Standardization Provides Cost-Saving, Efficiencies appeared first on School Transportation News.

This article examined nontraditional student transportation scenarios that fall outside standard home-to-school routes on school buses. It explored how districts are adapting to serve students with disabilities and special needs who need alternative schedules and specialized programs. The piece emphasized flexibility, collaboration and policy considerations required to safely and effectively manage atypical transportation models.

This article examined nontraditional student transportation scenarios that fall outside standard home-to-school routes on school buses. It explored how districts are adapting to serve students with disabilities and special needs who need alternative schedules and specialized programs. The piece emphasized flexibility, collaboration and policy considerations required to safely and effectively manage atypical transportation models. Focusing on one of the most persistent safety threats in pupil transportation, this article addresses strategies to reduce illegal passing of stopped school buses. It highlighted the role of public awareness campaigns, stop-arm cameras, and enforcement partnerships, reinforcing the importance of both education and technology in protecting students at bus stops.

Focusing on one of the most persistent safety threats in pupil transportation, this article addresses strategies to reduce illegal passing of stopped school buses. It highlighted the role of public awareness campaigns, stop-arm cameras, and enforcement partnerships, reinforcing the importance of both education and technology in protecting students at bus stops. Procurement and decision-making challenges faced by transportation departments, particularly as districts evaluate new vehicles, services and technologies, underscore the importance of planning, transparency and stakeholder input when making large-scale transportation investments.

Procurement and decision-making challenges faced by transportation departments, particularly as districts evaluate new vehicles, services and technologies, underscore the importance of planning, transparency and stakeholder input when making large-scale transportation investments. One of the most-read magazine articles of the year looked at emerging AI trends shaping student transportation. Topics include predictive maintenance technologies, data-driven operations and forward-thinking approaches to safety and efficiency. The article encouraged readers to view innovation as a proactive tool rather than a reactive solution.

One of the most-read magazine articles of the year looked at emerging AI trends shaping student transportation. Topics include predictive maintenance technologies, data-driven operations and forward-thinking approaches to safety and efficiency. The article encouraged readers to view innovation as a proactive tool rather than a reactive solution.

Celebrating a decade of recognizing excellence, this article highlights the critical role maintenance professionals play in student transportation. It honored the dedication, expertise and behind-the-scenes work of garage staff who keep fleets safe, reliable and road-ready every day.

Celebrating a decade of recognizing excellence, this article highlights the critical role maintenance professionals play in student transportation. It honored the dedication, expertise and behind-the-scenes work of garage staff who keep fleets safe, reliable and road-ready every day. This article explores technology solutions designed to support long-term transportation goals rather than short-term fixes. Topics included vehicle systems, software integration and tools that improve safety, accountability, and operational visibility for transportation departments.

This article explores technology solutions designed to support long-term transportation goals rather than short-term fixes. Topics included vehicle systems, software integration and tools that improve safety, accountability, and operational visibility for transportation departments.

The most-viewed magazine article of 2025 spotlighted emerging leaders in the student transportation industry. By recognizing rising professionals making meaningful contributions, the article reflects the industry’s focus on mentorship, succession planning and cultivating the next generation of transportation leadership.

The most-viewed magazine article of 2025 spotlighted emerging leaders in the student transportation industry. By recognizing rising professionals making meaningful contributions, the article reflects the industry’s focus on mentorship, succession planning and cultivating the next generation of transportation leadership.

is designed to ensure every fleet runs efficiently.

is designed to ensure every fleet runs efficiently.