Importance of First Responder Coordination for School Bus Emergencies at STN EXPO East

Two student transportation professionals at STN EXPO East will discuss how transportation departments can set up a collaborative partnership with local police and fire departments to aid in safe emergency response.

Tracie Franco, director of transportation at Leander Independent School District in Texas, will join Joshua Hinerman, state director of student transportation at the Tennessee Department of Education and former director of transportation for Robertson County Schools near Nashville, in a panel discussion facilitated by STN Editor in Chief Ryan Gray March 29.

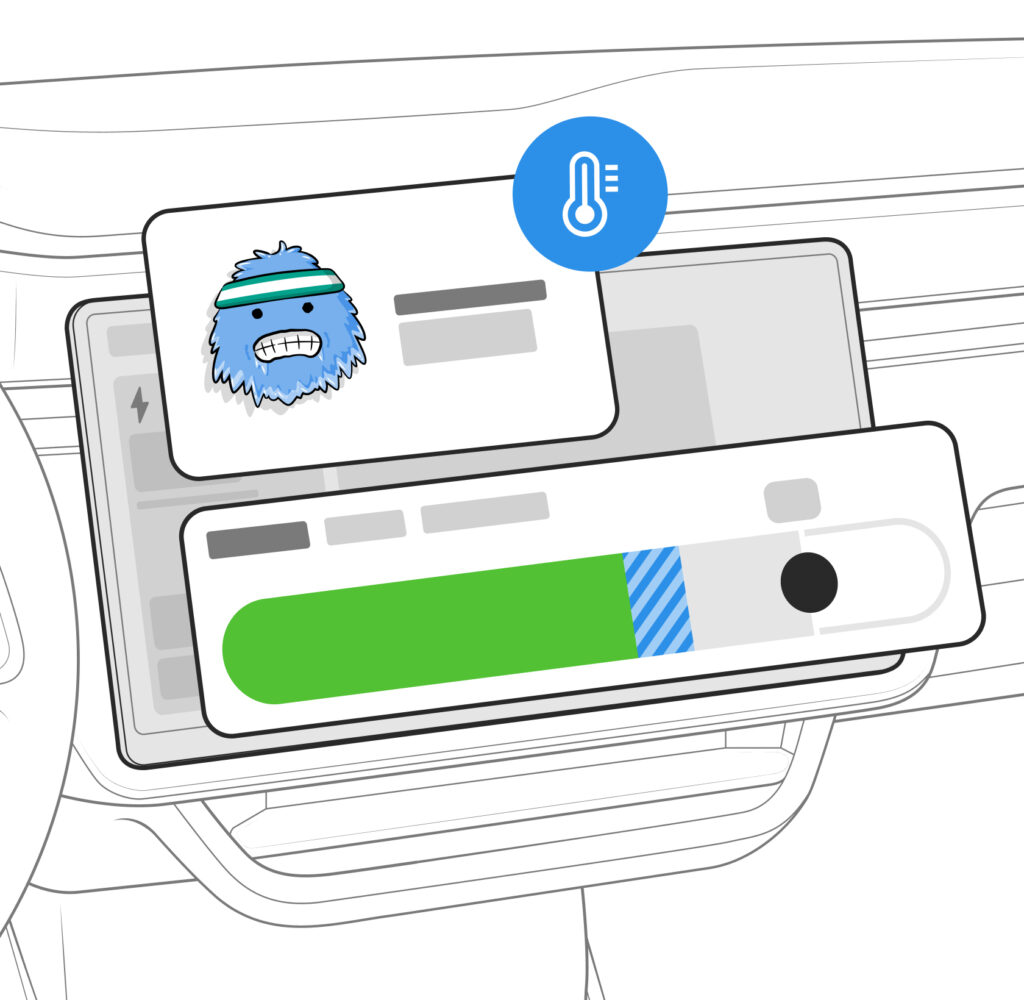

They will share tips to proactively reach out and train with emergency first responders to make sure they are aware of the unique response and recovery efforts needed for a school bus incident. They will discuss coordinated training and in-service efforts, student ridership technology that can provide instant access to crucial information in an emergency and making sure transportation departments are engaging with the district wide community to increase awareness on safety efforts.

Attendees will leave the session with a better understanding of the logistics related to involving first responders in emergency response best practices in their student transportation department and strategies to improve their incident response protocol.

The session will provide attendees with practical strategies to work with law enforcement, fire, EMS and other emergency management agencies in preparing response to school bus emergencies. Franco and Hinerman will discuss their personal experiences with school bus crashes and lessons learned on joint training with first responders.

The session will provide attendees with practical strategies to work with law enforcement, fire, EMS and other emergency management agencies in preparing response to school bus emergencies. Franco and Hinerman will discuss their personal experiences with school bus crashes and lessons learned on joint training with first responders.

The STN EXPO East conference will be held on March 26-31 at Embassy Suites by Hilton Charlotte Concord Golf Resort & Spa. Main conference registration gives access to five days of educational sessions, hands-on training, unique networking events, product demonstrations and updates on the latest industry happenings. Register at stnexpo.com/east.

Related: STN EXPO East Addresses Safety Concerns in School Bus Loading Zone

Related: NTSB to Provide School Bus Investigation Updates at STN EXPO East

Related: STN EXPO East to Feature Illegal Passing Trends, Safety Recommendations

The post Importance of First Responder Coordination for School Bus Emergencies at STN EXPO East appeared first on School Transportation News.